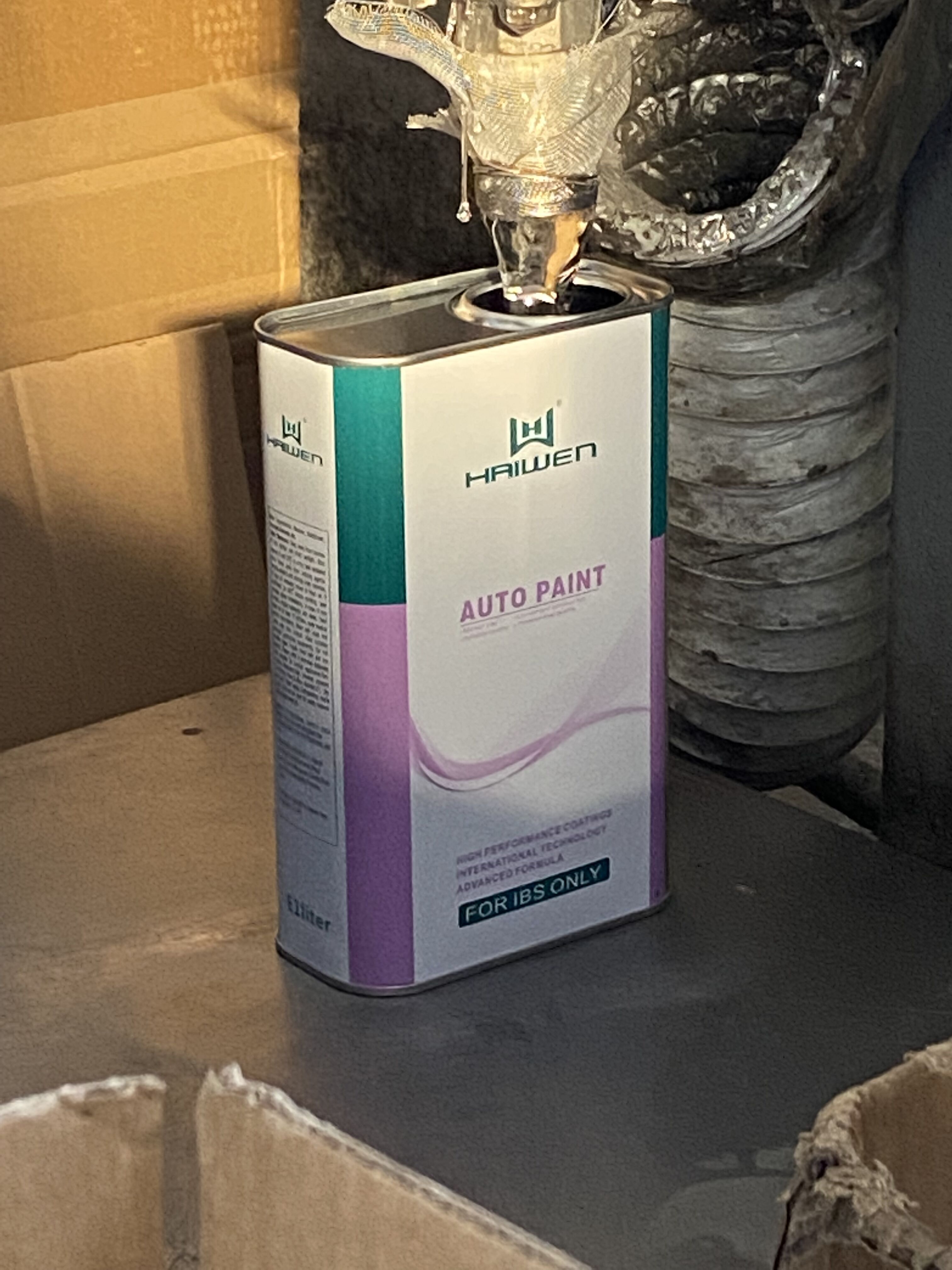

acrylic paint factory

An acrylic paint factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality acrylic-based paints and coatings. These facilities combine advanced chemical processing equipment with precision mixing technology to create versatile paint products suitable for various applications. The factory typically features automated production lines equipped with sophisticated temperature and humidity control systems, ensuring consistent product quality. Key components include raw material storage units, mixing vessels, grinding mills for pigment dispersion, quality control laboratories, and automated packaging systems. Modern acrylic paint factories utilize computer-controlled batch processing systems that monitor and adjust formulation parameters in real-time. The facility's production capabilities extend to manufacturing water-based acrylic paints, textured coatings, primers, and specialized finishes. Environmental control systems manage air quality and waste disposal, adhering to strict environmental regulations. The factory's research and development department continuously works on developing new formulations, improving existing products, and conducting quality assurance tests. Storage facilities maintain optimal conditions for both raw materials and finished products, while the logistics department manages efficient distribution networks. This comprehensive manufacturing ecosystem ensures the delivery of reliable, high-performance acrylic paint products to various market segments.